Retrofitting Teradata for SAP ECC to SAP S4 Hana Migration

About the Client:

Client is a leading global manufacturer of confectionery and snack products since 1880s. With a rich heritage and a portfolio of well-known brands, the company has established itself as a household name in the food and beverage industry. Client operates in over 80 countries and generates billions of dollars in annual revenue.

Background:

The client, a prominent multinational company operating in the food and beverage industry, had been using an aging SAP legacy system that was built back in 1998. Over time, they had made some upgrades by implementing SAP BW Hana for their business warehouses. However, their ERP system had not been updated, causing inefficiencies and limitations in their operations. To address these issues, the client decided to leverage SAP Hana technology and embarked on a phased implementation starting with their Mexico, US, and Canada business units.

Challenge with Legacy system:

- Inadequate Support for New Business Demands

- Connectivity Issues with New Systems

- Managing Large Data Volumes

Type of Approach

Green Field

Reporting tools

Power BI / Tableau

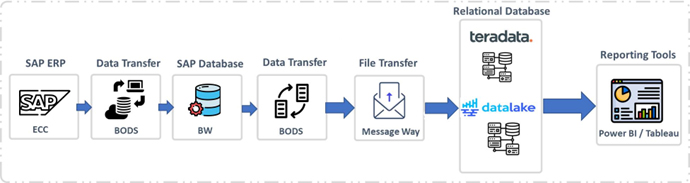

Relational Database

Teradata, Datalake

Approach:

- Green field approach was applied for the project with agile development strategy

- Parallel system was created so that current operations are not affected

- Development and test environment were created

Solution:

- Created inventory of existing objects

- Checked with the different application teams on the availability of source files in S4

- Have a design ready to Implement an existing Teradata object in S4

- Develop necessary scripts and objects as per the design specified (from business owners)

- Test the developed code for any for issues or bugs

- Source system JDA during testing we found that a lot of records were moving to exception table due to discrepancy in data from dependent tables.

- We analyzed this issue and found the root cause to be unavailability of “000 materials” in mvke file, we got back to business with our observation and as a result, we went ahead a design change of mvke transform script to fix this issue.

Outcome:

- Ordering system overhaul

- Better insights on stocks

- Demand planning